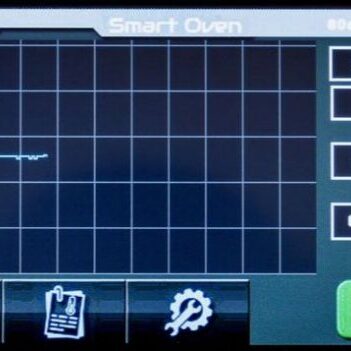

NT-32 SMART CURING OVEN A top load version of the SMART OVEN with 4.3″ touch screen display, cure up to 60 connectors at a time (standard 32 Conn) Super stable temperatures, Ramp/Soak functions , All popular epoxies stored in memory

Description

Fiber Optic Curing Oven

NT-32 Smart Top Curing Oven

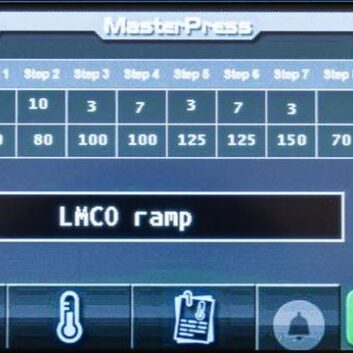

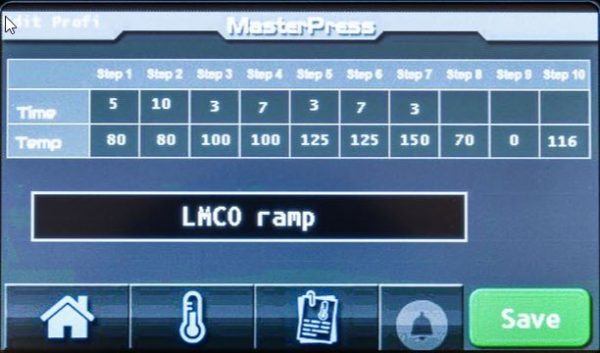

Epoxy Selection Menu for Process Control

A top load version of the SMART OVEN with 4.3" touch screen display, cure up to 60 connectors at a time ( standard 32 Conn.) Super stable temperatures, Ramp/Soak functions, All popular epoxies stored in memory

Cure 32 connectors at a time

Precise Control

Epoxy Selection Menu for Process Control

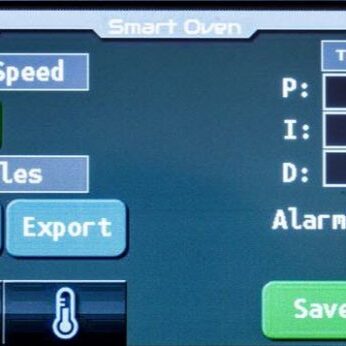

7-inch touch screen with 30 recipes storing all major Mfg epoxy cure times/temps. ensure accurate repeatable performance. Ramp/Soak function for Mil Spec. applications

Cure many types of connectors

Epoxy Selection Menu for Process Control

Fiber Optic Curing Oven Most Connectors including MT

The NT-32 works with most 2.5 & 1.25 Ferrules and custom applications

Made In USA (Since 1993)

Frank Bertotti

FiberRep ... Knowledge, Service & Support!

805-748-7790

fjb@bertotti.org

West Coast Manufacturer's Exclusive Representative

PolishingCleaningInterferometryInspection